OkiePC, I know what is wrong with you!

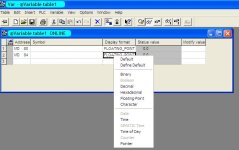

Looks like the only thing missing (aside from Peter's valid point about consistency of terminology) is a drop down arrow so you don't have to guess where to right click.

You think like an American!!!

It must be a disease that you are catching from other Americans, oh sh!t we can't have that. Of course the Germans think we are stupid. LD must think we are stupid too.

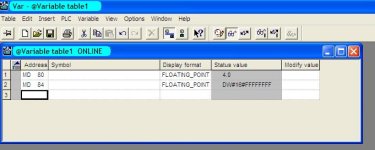

Yes, I looked for the tab on the right of the text box that shows all the valid options but the Siemens programmers are too lazy to display the options.

I wonder how much time it would take a software programmer to add the options versus all the customers that waste time looking up what the options are? It might take the software programmer a day if he is incompetent but think of all the days his customer will save.

LD, I don't want to spend any more time that I have to supporting our product with any PLC. I just can't understand why I speed about 100 times more time supporting customers using Siemens PLCs.

This last customer had problems because his old crippled PLC DIDN'T SUPPORT THE MAX NUMBER OF REGISTERS THAT CAN BE TRANSFERRED WITH DATA CONSISTENCY. That is a PLC problem not mine. I resent having to support the deficiency in a Siemens product.

The customers should be asking Siemens why they can transfer 64 32 bit registers back and forth with data consistency.

This problem has mostly gone away with ProfiNet but the Profibus user are still very limited in the amount of data they can transfer.