MelissaMiranda

Member

So, I have my first real job interview this week...and I'm pretty nervous but also VERY excited.

Just graduated as a junior industrial automation engineer. This is my first "real" job interview and man I never thought it would be this exhausting. Can't really imagine how further exhausting it will be to land a full-time job where your brain is constantly "on". Love the field though.

I have to go through a handful of tests: Some personality and IQ tests and lastly I have to solve a case and then present it. The case is actually what I fear the most because I don't really know how to solve it with the little information they've given me in the task. I feel really stupid but I have zero experience with parcel conveyors so I kinda lack the imagination of how one should be designed.

I don't have to design everything from scratch. I have the layout of the whole system. But I need to think about where to place the sensors (for gap detection purposes), mind the required spacing between the parcels (250mm), parcel length (300x300x100mm) and main speed of conveyor of 2.1 m/s.

Here's the exact task:

Your task is to meet the customer requirement of 4000 parcels/hr. in the

dimension 300x300x100mm.

Limitations:

1. Main conveyor feeding line speed can maximum be 2,1 m/s to be within the specifications of the sorter line. Line sorter speed = Main conveyor line speed. The line sorter and main

conveyor feeding line has to run continuously

2. Spacing between parcels must be a minimum of 250 mm upon handover to the line sorter.

3. No conveyor in the system are designed to have a velocity higher than 3,5 m/s or an

acceleration above 4,0 m/s^2.

Task:

As a minimum include your thoughts on:

1. sensor placement (how many and where?)

2. max. capacity for a single BOM feeding line.

3. critical areas that would require attention during development/commissioning

So, there I have it. I'm just puzzled how to figure out the max capacity when I don't have more info of the conveyor dimensions? Maybe I'm missing something? I'm pretty nervous about the interview so my brain is already cloudy .

.

I changed profession three years ago because I wanted to try something new. Always dreamed of being an "engineer" but never got to do anything about it (because girls just weren't engineers at the time I was a teen in the early 2000s). So I ended up working with HR. The learning curve has been steep but I've managed to get good grades but the "real world" is just so much more complex than what you learn in the university.

I'm not looking for solutions handed to me but maybe some guidance of where to start? If you need an overview drawing of the system, please let me know.

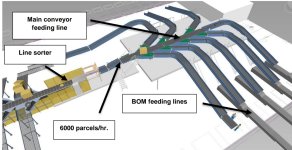

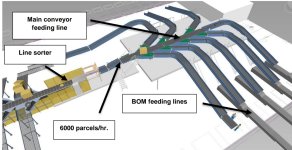

Edit: attached drawing of the layout

Thank you in advance

/Melissa Miranda

Just graduated as a junior industrial automation engineer. This is my first "real" job interview and man I never thought it would be this exhausting. Can't really imagine how further exhausting it will be to land a full-time job where your brain is constantly "on". Love the field though.

I have to go through a handful of tests: Some personality and IQ tests and lastly I have to solve a case and then present it. The case is actually what I fear the most because I don't really know how to solve it with the little information they've given me in the task. I feel really stupid but I have zero experience with parcel conveyors so I kinda lack the imagination of how one should be designed.

I don't have to design everything from scratch. I have the layout of the whole system. But I need to think about where to place the sensors (for gap detection purposes), mind the required spacing between the parcels (250mm), parcel length (300x300x100mm) and main speed of conveyor of 2.1 m/s.

Here's the exact task:

Your task is to meet the customer requirement of 4000 parcels/hr. in the

dimension 300x300x100mm.

Limitations:

1. Main conveyor feeding line speed can maximum be 2,1 m/s to be within the specifications of the sorter line. Line sorter speed = Main conveyor line speed. The line sorter and main

conveyor feeding line has to run continuously

2. Spacing between parcels must be a minimum of 250 mm upon handover to the line sorter.

3. No conveyor in the system are designed to have a velocity higher than 3,5 m/s or an

acceleration above 4,0 m/s^2.

Task:

As a minimum include your thoughts on:

1. sensor placement (how many and where?)

2. max. capacity for a single BOM feeding line.

3. critical areas that would require attention during development/commissioning

So, there I have it. I'm just puzzled how to figure out the max capacity when I don't have more info of the conveyor dimensions? Maybe I'm missing something? I'm pretty nervous about the interview so my brain is already cloudy

I changed profession three years ago because I wanted to try something new. Always dreamed of being an "engineer" but never got to do anything about it (because girls just weren't engineers at the time I was a teen in the early 2000s). So I ended up working with HR. The learning curve has been steep but I've managed to get good grades but the "real world" is just so much more complex than what you learn in the university.

I'm not looking for solutions handed to me but maybe some guidance of where to start? If you need an overview drawing of the system, please let me know.

Edit: attached drawing of the layout

Thank you in advance

/Melissa Miranda