We have all seen this driving down the road,

Couldn't you be a little bit more specific? What "this"?

But when someone can explain to me how the wheel on a car moving down a highway can operate with sustained vertical oscillation WITHOUT a PID driving it into that oscillation

Such incredible technical innovations like springs and

shock absorbers suspension haven't made it to the US yet?

(Strictly speaking, this is not a PID controller, but things are comparable. If your shock absorber collapses and you get into resonant bumps, I suppose you will reconsider your opinion. By the way, have you driven car with unbalanced wheels?)

then and only then will I believe

If this is the king's will,

the despicable worms

cannot but obey

you can stop the OP's oscillation by reducing gains ANYWHERE in the system. I fully believe you will need a gain to get you OUT of the oscillation but I am EXTREMELY dubious that it is a gain putting you into oscillation.

Please feel free to calculate closed loop step response

Plant TF

Wp(s) = 1/ ( (10*s)^2 + 2 * 0.2 * 10 * s + 1)

PI TF1

Wc(s) = 0.1 *(1 + 10 / s)

PI TF2

Wc(s) = 1 *(1 + 10 / s)

And I also think that it would be more useful for everyone if, before writing something in a topic, this topic would be read.

This post, as it seems to me, is not related to the OP issue.

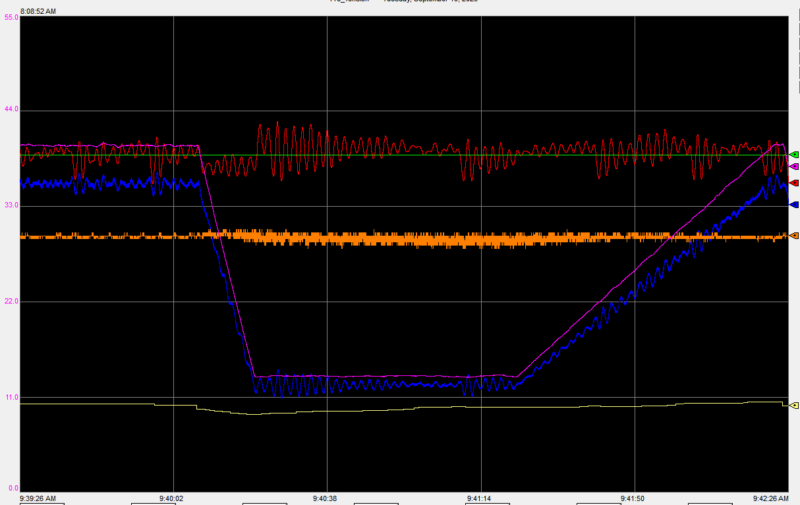

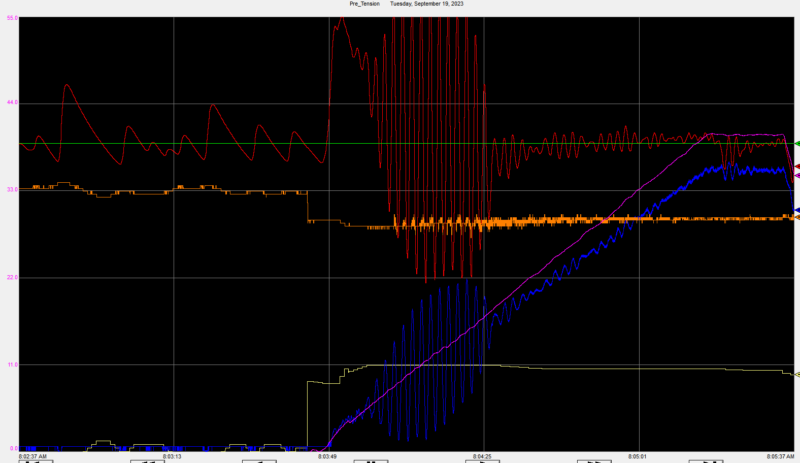

In linear (described by LDE) systems, oscillations with constant amplitude are impossible (on the OP curves amplitude is constant). Thus, I assume that there is an element with oscillation restrictions in the system (for example, a roller with a destroyed damping system, as a result of which it oscillates between mechanical stops - not yet destroyed structural elements). It would be more correct to repair the faulty element (such faults leave "traces": noise, vibration, shock, mechanical marks, etc.), but the mechanical staff hopes that the control system staff will get a magic wand and fix everything.

Let's return to the issue.

Because the system oscillates with a fairly clear self-oscillation frequency, then I believe that by changing the PID controller setting, it is possible to shift the frequency of the system relative to the frequency of self-oscillation of the faulty element. Or, by introducing a deadband into the PID controller, make the PID controller insensitive to idle self-oscillations.

BUT it may turn out that all my guesses are not worth a penny.