Mas01

Member

I'm new to S7/TIA.

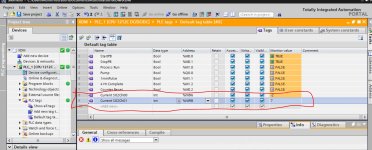

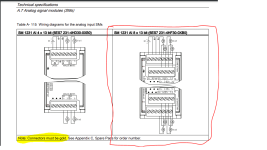

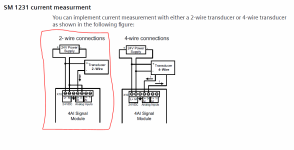

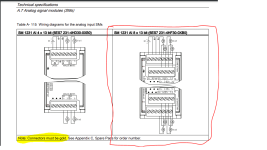

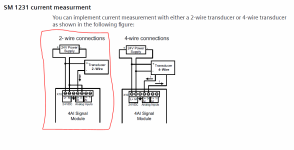

There's no devices connected to the PLC yet. I've got a laser measurement sensor (Micro-Epsilon optoNCDT 1220). From the paperwork, it's a 2-wire device (red +24V, White 0V current output, I think). My question is not so much about wiring it ( I have the diagram for that from the manual, see pic)...but if I physically connect it to Channel 0, how do I configure ch0 for a 4-20mA input (as opposed to say 0-5V) in the software? Ultimately, I want to measure the distance from the sensor head to the object directly in front of it, and monitor the value (at least the raw digital value) on TIA software. Thanks, and sorry for the basic question - I'll also see if there's any online videos w.r.t. this question.

There's no devices connected to the PLC yet. I've got a laser measurement sensor (Micro-Epsilon optoNCDT 1220). From the paperwork, it's a 2-wire device (red +24V, White 0V current output, I think). My question is not so much about wiring it ( I have the diagram for that from the manual, see pic)...but if I physically connect it to Channel 0, how do I configure ch0 for a 4-20mA input (as opposed to say 0-5V) in the software? Ultimately, I want to measure the distance from the sensor head to the object directly in front of it, and monitor the value (at least the raw digital value) on TIA software. Thanks, and sorry for the basic question - I'll also see if there's any online videos w.r.t. this question.

Last edited: