You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

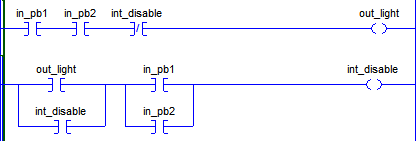

Anti -Tie Down - Non Repeat - No Timer

- Thread starter raydog26

- Start date

wolverine1981

Member

raydog26

I am with kamenges on this one. I think your assignment is great. Reading the last sentence of the description of your project I'm pretty sure you need to engineer a timer. Otherwise you would be able to wedge button one down, then place one hand in the machine while pressing the button 2 with the other.

I have'nt done much programming for RSLogix but some other brands have special internal bits or relays that work off the clock of the cpu (S:4 Free Running Clock).

This is only my opnion but the professor maybe teaching the students to read, research, ask questions and think outside the box on this one.

Tom

I am with kamenges on this one. I think your assignment is great. Reading the last sentence of the description of your project I'm pretty sure you need to engineer a timer. Otherwise you would be able to wedge button one down, then place one hand in the machine while pressing the button 2 with the other.

I have'nt done much programming for RSLogix but some other brands have special internal bits or relays that work off the clock of the cpu (S:4 Free Running Clock).

This is only my opnion but the professor maybe teaching the students to read, research, ask questions and think outside the box on this one.

Tom

Last edited:

thank you both for your insight and wisdom its appreciated. I plan to try all the examples shown so far to see if they all work as described then hopefully i can wrap my head around the concept further so i do understand and learn how to figure such issues out if they ever arise again. we just started covering timers in class after this assignment was given which is why he didnt want us using them yet.

TurpoUrpo

Lifetime Supporting Member

I disagree on timer and out of box thinking.raydog26

I am with kamenges on this one. I think your assignment is great. Reading the last sentence of the description of your project I'm pretty sure you need to engineer a timer. Otherwise you would be able to wedge button one down, then place one hand in the machine while pressing the button 2 with the other.

I have'nt done much programming for RSLogix but some other brands have special internal bits or relays that work off the clock of the cpu (S:4 Free Running Clock).

This is only my opnion but the professor maybe teaching the students to read, research, ask questions and think outside the box on this one.

Tom

Its basic ladder, not something fancy. There is limit on what can be asked of people who have not worked for 20 years on plc's but are total newbies with them.

Something simple for us is not simple for one who has never really done anything!

Pardon me, but I have to slip in a word of caution.

You cannot create a do-it-yourself safety circuit, and use it in a real-world situation.

You must either use an approved safety relay, or a safety PLC with dedicated safety program blocks.

It may be an excercise in programming, but dont use this excercise as a pretext to that you can rely on regular PLC code for a machine safety function.

!raydog26 said:I think the man reason for this exercise is to show the importance of writing a code that is safe for the operator because if it is wrong injury and/or death can occur.

You cannot create a do-it-yourself safety circuit, and use it in a real-world situation.

You must either use an approved safety relay, or a safety PLC with dedicated safety program blocks.

It may be an excercise in programming, but dont use this excercise as a pretext to that you can rely on regular PLC code for a machine safety function.

Brijm

Lifetime Supporting Member

yes you are correct. he told us in class no timers. he used to give this assignment for a grade but to many students got frustrated and quit because they couldn't figure it out so now it is extra credit assignment.

I would ask for clarity on the anti-tiedown. Normally by definition, an anti-tiedown circuit has a time that both the pushbuttons need to be pressed within. I'm doubting that your professor wants you to build a timer, so I beleive that the description that Steve Etter is close to what he is wanting.

Now for the anti-repeat. Normally for a punch-press control, you would have a PLS (Cam) window near Top of stroke for the anti-repeat. On older presses I've also seen this done with a timer, where the buttons are only active for a time less than the Press cycle time, but long enough to reach 180° where the operator is allowed to release the buttons in single cycle mode (The auto-up is held in by a PLS (Cam)) The Operator must then release both buttons to reset the timer and activate the buttons again. (Note: this certainly does not meet ansi standards)

With no inputs for where the press is in the cycle, I can't see how you would do it without a timer. I would ask for more of a description of exactly what he is wanting.

OkiePC

Lifetime Supporting Member

I was thinking of writing one like that using six or seven cascading bits to act as scan counters to meet the test requirements and actually have one capable of working with a real human and two separate buttons (if the PLC is slow enough, a few scans tolerance on button press timing might get us close to 100ms).Is it possible the professor is looking for series of b3 outputs going upwards to use the plc scan time as a timer - he did say you can use as many b3 coils as you like.

Paul

gtsuport

Member

JesperMP,

Could not agree with you more.

This may be a valid programming exercise, but it is not correct to use in a real world application. Reference OSHA 1910, Power Press standard.

Could not agree with you more.

This may be a valid programming exercise, but it is not correct to use in a real world application. Reference OSHA 1910, Power Press standard.

Can you use latched outputs?

so latch an output when both are pressed, Unlatch when both released.(is a 3 line code the labels and rungs are on diff lines)

----b1---b2-----------out1

----[ ]---[ ]-----------(L)--

---- b1---b2-----------out1

----[/]---[/]-----------(U)--

----out1-----------Drill activate

----[ ]----------------( )--

I would even add a oneshot so drill is only activated once. then change last line to

---out1--- out_bit-- -drill activate

--[ ]----[ONS]--------( )

no clue if your plc supports that stuff

so latch an output when both are pressed, Unlatch when both released.(is a 3 line code the labels and rungs are on diff lines)

----b1---b2-----------out1

----[ ]---[ ]-----------(L)--

---- b1---b2-----------out1

----[/]---[/]-----------(U)--

----out1-----------Drill activate

----[ ]----------------( )--

I would even add a oneshot so drill is only activated once. then change last line to

---out1--- out_bit-- -drill activate

--[ ]----[ONS]--------( )

no clue if your plc supports that stuff

Last edited:

Similar Topics

Good day all. I have a machine to automate. It is a 2-ton heat press. It moulds small plastic parts. The mould cycle is initiated after the...

- Replies

- 6

- Views

- 3,086

I searched and could not find an answer.

The machine is a pneumatic press,two cylinders 32mm bore.

Can this machine be built per OSHA safety...

- Replies

- 7

- Views

- 3,737

Can someone show me an example of an anti tie down program? I am using micrologix 1200.

- Replies

- 3

- Views

- 5,732

I am setting up an educational work cell in my University's automation lab. It is a senior thesis project and will be used for educational...

- Replies

- 28

- Views

- 8,673

Is there away to program palm buttons using

only one timer in the anti tie down ??

- Replies

- 36

- Views

- 18,323