OkiePC

Lifetime Supporting Member

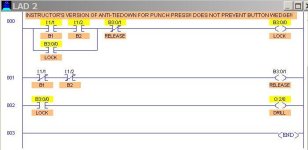

I still think it will be tricky to time it with two real push buttons.

A 5/02 is slower than a micrologix or a 5/05, though, so that would help. I could always add a half dozen more rows and columns to count more scans, and there is probably a more compact way of writing it to get the effect. Maybe a 10 scan tolerance for only one button.

A 5/02 is slower than a micrologix or a 5/05, though, so that would help. I could always add a half dozen more rows and columns to count more scans, and there is probably a more compact way of writing it to get the effect. Maybe a 10 scan tolerance for only one button.