Hey everyone I'm working on a PLC project for a series of 4 vacuum pumps. I need to be able to rotate each pump into a different priority based on run time.

So we have a factory that runs vacuum packers. Sometimes we run 5 some times we run 1. I have already created the program and turns the pumps on and off based on the demand. The more draw the more pumps turn on the less draw the more pumps turn off after a set amount of time.

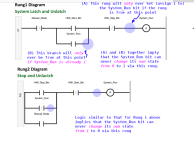

Now however pump 1 has 4 times the amount of run time as pump 4. So I am trying to find a way to get the pumps to rotate into a priority position based on the amount of run time.

I don't think I need comparators for all four pumps, I was thinking that if I just take all the timer readings from all 4 pumps and just set it to say when one pump is more them 250 hours less than the others it goes to priority one. There would be no need to check for priorities 2, 3, and 4. If you just rotate the lowest hours pump into priority then it should keep all 4 pumps more or less even within the range set...... But then how would you write that in CCW...

Any help would be greatly appreciated.

So we have a factory that runs vacuum packers. Sometimes we run 5 some times we run 1. I have already created the program and turns the pumps on and off based on the demand. The more draw the more pumps turn on the less draw the more pumps turn off after a set amount of time.

Now however pump 1 has 4 times the amount of run time as pump 4. So I am trying to find a way to get the pumps to rotate into a priority position based on the amount of run time.

I don't think I need comparators for all four pumps, I was thinking that if I just take all the timer readings from all 4 pumps and just set it to say when one pump is more them 250 hours less than the others it goes to priority one. There would be no need to check for priorities 2, 3, and 4. If you just rotate the lowest hours pump into priority then it should keep all 4 pumps more or less even within the range set...... But then how would you write that in CCW...

Any help would be greatly appreciated.