You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can you recommend the proper direction on SLC500

- Thread starter xcode

- Start date

Hi everyone.. I am on the happy wagon now. Finally figured out how to get the 5/03 online and even stuffed my first program to it. No more blinking red light.

Now, I can program my Proface today, I can program my 5/03. Now it is on to the ladder logic.

I have drawn all the schematic and flowcharting of the needs to where I must go with the circuits. Hardware is easy for me if I know where the software is coming from with what.

Originally I was thinking one rung with a simple "see a 1" , 'go write a 1' . 1 on the relay, close the relay. The time however for the relay to stay closed is important if the button is just sit there and held. The relay can only stay closed for 500ms there about. That will cover 80% of the buttons I need duplicated. The other 20% need to be push once on/ push again off.

Push once on push again off to me is flip flop.

Push once and get a relay to close is OSR. Each push generates a OSR.

thanks for the help.

Now, I can program my Proface today, I can program my 5/03. Now it is on to the ladder logic.

I have drawn all the schematic and flowcharting of the needs to where I must go with the circuits. Hardware is easy for me if I know where the software is coming from with what.

Originally I was thinking one rung with a simple "see a 1" , 'go write a 1' . 1 on the relay, close the relay. The time however for the relay to stay closed is important if the button is just sit there and held. The relay can only stay closed for 500ms there about. That will cover 80% of the buttons I need duplicated. The other 20% need to be push once on/ push again off.

Push once on push again off to me is flip flop.

Push once and get a relay to close is OSR. Each push generates a OSR.

thanks for the help.

bernie_carlton

Lifetime Supporting Member + Moderator

I appreciate that direction on the relay setup Bernie. I have the easy parts of the ladder logic done and loaded to the 5/03. I can run the program, toggle the bits, and I get the relays on and off, and see the respective lights on the ow16 module. Sweet...

However, if I thought the documentation was bad on the setup of RSLinx to the SLC 500, the documentation for setting up the Proface 577R to the SLC500 is really really bad.

I have 2 cable configurations for the same part number. Tried them both built each way, and still no joy.

Cable is suppose to be HMI-CAB-C52 .. The PDF for this shows a difference in PLC port wiring of pins 7 , 8 , 1 .. they are tied together on some of Rockwell's PDF's and then the GP577R PDF shows 6, 4, 1 .. tied together instead.

More reading unless someone can chime in on this and seen problem already.

However, if I thought the documentation was bad on the setup of RSLinx to the SLC 500, the documentation for setting up the Proface 577R to the SLC500 is really really bad.

I have 2 cable configurations for the same part number. Tried them both built each way, and still no joy.

Cable is suppose to be HMI-CAB-C52 .. The PDF for this shows a difference in PLC port wiring of pins 7 , 8 , 1 .. they are tied together on some of Rockwell's PDF's and then the GP577R PDF shows 6, 4, 1 .. tied together instead.

More reading unless someone can chime in on this and seen problem already.

Figured I would update this.

More light at the end of the tunnel. From 6pm yesterday to 4am this morning it was work on getting the Proface GP577R talking to the SLC 500 5/03 CPU. Wow, what fun. The cable for the RS232 I built was correct for one schematic I found, then I found another schematic and modified the cable. That still did not work. I trashed that cable and switched to DH485 building a cable from a schematic that read " DO NOT build this cable " buy it. However, here is the schematic to built it. Sweet, I built it. I will buy it however later when I find one for about $20. I never like my build cables for computers really. I would rather just buy the correct cable, but at 1am in the morning when you decide it is time to change direction, you do what you have to do.

Finally the 577R was seeing the 5/03. However, now there was address issues, GP PRO PBIII sending stuff to the 577R it really should not, the modifications to get all this to work finally fell into place about an hour ago. 577R can turn on and off the relays on the OW16.

If you get an error PLC Com error 02:10 , its not the cable, its not the address structure in the PLC like the documents state. Its alot of check boxes in GP PRO PBIII that need to be unchecked so the downloaded information is not stepping on addressing in the PLC.

More light at the end of the tunnel. From 6pm yesterday to 4am this morning it was work on getting the Proface GP577R talking to the SLC 500 5/03 CPU. Wow, what fun. The cable for the RS232 I built was correct for one schematic I found, then I found another schematic and modified the cable. That still did not work. I trashed that cable and switched to DH485 building a cable from a schematic that read " DO NOT build this cable " buy it. However, here is the schematic to built it. Sweet, I built it. I will buy it however later when I find one for about $20. I never like my build cables for computers really. I would rather just buy the correct cable, but at 1am in the morning when you decide it is time to change direction, you do what you have to do.

Finally the 577R was seeing the 5/03. However, now there was address issues, GP PRO PBIII sending stuff to the 577R it really should not, the modifications to get all this to work finally fell into place about an hour ago. 577R can turn on and off the relays on the OW16.

If you get an error PLC Com error 02:10 , its not the cable, its not the address structure in the PLC like the documents state. Its alot of check boxes in GP PRO PBIII that need to be unchecked so the downloaded information is not stepping on addressing in the PLC.

I need some help please. I have down loaded the 10 ways to do a push button on/off from the files archive. Lancie I am sure had something to do with that. Thank you.

I see one problem for someone like me with all the documents and Utube videos I watched. It all seems to always talk about a real world switch as in hardware. Estops, Auto ON/OFF buttons, stuff that is NO NC. I see very little about a HMI Panel talking to the PLC and how it addresses to the input of the CPU.

I figured out how to turn on 2 relays with my HMI. The Proface software used B3:0/0 as the address, and it was easy to do the XIC with two OTE's assigned to the OW16 in parallel and turn on those. However, they would not turn back off. OK, I know flip flop would be the answer. I build every one of the ladders that was in that file. About 3 I actually got to do something, but that something was still not right. One of them was like a christmas lights. I had blinking green bars flashing everywhere, but the relays on the OW16 just stayed on anyway.

Could someone please provide a ladder with a HMI interfaced input proceedure and it is a button pushed, and it is one shot on, and right back off. 500ms is long enough on if a timer has to be used. I thought of this too, but I could not make that work.

TIA

I see one problem for someone like me with all the documents and Utube videos I watched. It all seems to always talk about a real world switch as in hardware. Estops, Auto ON/OFF buttons, stuff that is NO NC. I see very little about a HMI Panel talking to the PLC and how it addresses to the input of the CPU.

I figured out how to turn on 2 relays with my HMI. The Proface software used B3:0/0 as the address, and it was easy to do the XIC with two OTE's assigned to the OW16 in parallel and turn on those. However, they would not turn back off. OK, I know flip flop would be the answer. I build every one of the ladders that was in that file. About 3 I actually got to do something, but that something was still not right. One of them was like a christmas lights. I had blinking green bars flashing everywhere, but the relays on the OW16 just stayed on anyway.

Could someone please provide a ladder with a HMI interfaced input proceedure and it is a button pushed, and it is one shot on, and right back off. 500ms is long enough on if a timer has to be used. I thought of this too, but I could not make that work.

TIA

Are you saying that when you push the button image on your HMI, the bit comes on but stays on in the PLC? It sounds like maybe (not familiar with your HMI package) you've configured the button in your HMI as a maintained instead of a momentary. You should have the option in the HMI to configure the button so that when you press and hold it sets the bit to '1' and when you release the button it sets it back to '0'.

Now, if it doesn't do that, you can still use the maintained style. But it depends on how you need to use the button as to the best course of action. IF you need that button to stay on for awhile because of the way your logic is written, then you'll need to use a timer to reset it. If your logic is such that one scan of it being on is sufficient, then you can just unlatch it at the end of your program.

NOTE: If the B3:0/0 is used in only one place, you could put the OTU B3:0/0 in the same rung as the rest of the logic as the last parallel output branch.

So, unlatch at the end, just put XIC B3:0/0 OTU B3:0/0 in a rung at the end of your pogram. Then B3:0/0 will have a 1 in it for one scan only. If you have a bunch of these, say all in the B3:0 word, then you could just clear the entire word instead (XIC B3:0/0 CLR B3:0).

For, Timer, do XIC B3:0/0 TON T4:0 (500ms). Branch around T4:0 with XIC T4:0.DN OTU B3:0/0.

Now, if it doesn't do that, you can still use the maintained style. But it depends on how you need to use the button as to the best course of action. IF you need that button to stay on for awhile because of the way your logic is written, then you'll need to use a timer to reset it. If your logic is such that one scan of it being on is sufficient, then you can just unlatch it at the end of your program.

NOTE: If the B3:0/0 is used in only one place, you could put the OTU B3:0/0 in the same rung as the rest of the logic as the last parallel output branch.

So, unlatch at the end, just put XIC B3:0/0 OTU B3:0/0 in a rung at the end of your pogram. Then B3:0/0 will have a 1 in it for one scan only. If you have a bunch of these, say all in the B3:0 word, then you could just clear the entire word instead (XIC B3:0/0 CLR B3:0).

For, Timer, do XIC B3:0/0 TON T4:0 (500ms). Branch around T4:0 with XIC T4:0.DN OTU B3:0/0.

Last edited:

ok, I have another problem. How do you go from working just fine in the ladder logic to all the sudden not working? I know that is a really generic question, but I will try to describe.

I started with 3 buttons on the HMI. Those 3 buttons in the ladder logic and then downloaded to the 5/03. All was fine. I had relays a clicking like they were suppose to. I increased the ladder logic to 16 rungs, and I added 8 more buttons on the HMI. Watched my addressing 100% percent. I did not change a thing about the FIRST 3 buttons. Just downloaded to the 5/03 and downloaded to the HMI.

All the sudden the first 3 buttons that worked 100% are now not working. HMI buttons will not make any changes at the 5/03 at all. toogle the bits manually in RSlogix and it still only shows the green bar at the XIC. No green bars at the OTE on that rung. I toggled all 16 and did find on XIC that when green turned on one output on that rung, but not the other.

Makes no sense to me, and I am sure this notice typing about the subject makes no sense to you.

I feel better I told someone however. Maybe you happen to know the answer, or at least something I can try.

I started with 3 buttons on the HMI. Those 3 buttons in the ladder logic and then downloaded to the 5/03. All was fine. I had relays a clicking like they were suppose to. I increased the ladder logic to 16 rungs, and I added 8 more buttons on the HMI. Watched my addressing 100% percent. I did not change a thing about the FIRST 3 buttons. Just downloaded to the 5/03 and downloaded to the HMI.

All the sudden the first 3 buttons that worked 100% are now not working. HMI buttons will not make any changes at the 5/03 at all. toogle the bits manually in RSlogix and it still only shows the green bar at the XIC. No green bars at the OTE on that rung. I toggled all 16 and did find on XIC that when green turned on one output on that rung, but not the other.

Makes no sense to me, and I am sure this notice typing about the subject makes no sense to you.

I feel better I told someone however. Maybe you happen to know the answer, or at least something I can try.

First off, when you are toggling the bits in the XIC, make absolutely sure that you are ONLINE and in RUN mode. There's been many of us that's spent time on a problem toggling things, only to realize they are toggling OFFLINE or the PLC is not in RUN mode.

Next, to test, unplug the HMI communication. Then test your logic by toggling. That will eliminate the possibility of your HMI having something incorrect in the addressing and causing problems.

Next, are you writing all this logic in LAD2? If not, make sure your Ladder program is being scanned. LAD2 will need a JSR for each Ladder file you've added.

For each OTE address, do a find all and make sure there are no duplicate OTEs with the same address. You should only have one OTE for a given address. You can have multiple OTL/OTUs but in almost 99% of the cases, one OTE per address.

Next, to test, unplug the HMI communication. Then test your logic by toggling. That will eliminate the possibility of your HMI having something incorrect in the addressing and causing problems.

Next, are you writing all this logic in LAD2? If not, make sure your Ladder program is being scanned. LAD2 will need a JSR for each Ladder file you've added.

For each OTE address, do a find all and make sure there are no duplicate OTEs with the same address. You should only have one OTE for a given address. You can have multiple OTL/OTUs but in almost 99% of the cases, one OTE per address.

Thank you Robert.

The remote option is selected and it toggles between online, offline, run.. I like that remote selection now.

The HMI has one working button out of the 8, however, it is not turning on but one relay instead of two like it is suppose to.

Unplugged HMI however, and it same result. Toggle XIC and get only a green bar at it.

Please note I have one rung where I can toggle that XIC and get one relay to turn on. the other does not.

All rungs are in LAD2.

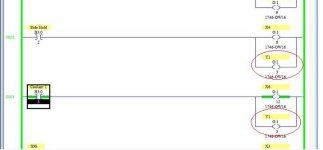

here is a pic of the ladder in run. I toggled the coolant bit and I get one relay on, and not 2. I know that the logic turning on another X6 in another rung, but the only Y1 is unique to this rung so it only suppose to turn on 2 relays.

The remote option is selected and it toggles between online, offline, run.. I like that remote selection now.

The HMI has one working button out of the 8, however, it is not turning on but one relay instead of two like it is suppose to.

Unplugged HMI however, and it same result. Toggle XIC and get only a green bar at it.

Please note I have one rung where I can toggle that XIC and get one relay to turn on. the other does not.

All rungs are in LAD2.

here is a pic of the ladder in run. I toggled the coolant bit and I get one relay on, and not 2. I know that the logic turning on another X6 in another rung, but the only Y1 is unique to this rung so it only suppose to turn on 2 relays.

milldrone

Member

For each OTE address, do a find all and make sure there are no duplicate OTEs with the same address. You should only have one OTE for a given address. You can have multiple OTL/OTUs but in almost 99% of the cases, one OTE per address.

I can see two Y1's, and I think there is at least one more, somewhere after your screenshotbut the only Y1 is unique to this rung so it only suppose to turn on 2 relays.

Last edited:

Yeah, you're committing a cardinal sin....

Think of an OTE instruction this way. All it does is write a 1 or a 0 to the bit location. The PLC scans from top to bottom. In your example, you have symbol Y1 in multiple places as an OTE. What happens is that on the first rung, if it is true, a 1 is written to Y1. But on the very next rung, it is false so a 0 is written to Y1. Remember, a PLC doesn't update its I/O until the END of the scan. So, the last thing the end of the scan sees is a 0 in Y1 and the output doesn't turn on. You need to re-write your program so that there is only ONE Y1 on an OTE instruction. If you have multiple things that can turn that Y1 on that's fine, but they need to be parallel branches in the one rung that has the Y1 OTE.

Think of an OTE instruction this way. All it does is write a 1 or a 0 to the bit location. The PLC scans from top to bottom. In your example, you have symbol Y1 in multiple places as an OTE. What happens is that on the first rung, if it is true, a 1 is written to Y1. But on the very next rung, it is false so a 0 is written to Y1. Remember, a PLC doesn't update its I/O until the END of the scan. So, the last thing the end of the scan sees is a 0 in Y1 and the output doesn't turn on. You need to re-write your program so that there is only ONE Y1 on an OTE instruction. If you have multiple things that can turn that Y1 on that's fine, but they need to be parallel branches in the one rung that has the Y1 OTE.

Similar Topics

Good Morning ,

I have worked with many robot integrators through the years ,and was looking at Pearson Packaging Systems . Have many of you used...

- Replies

- 4

- Views

- 2,206

Hello PLCS.net!

I'm about to program my first Robot soon! It's going to be a Fanuc.

But wait, there's more! It's also going to be collaborative...

- Replies

- 4

- Views

- 3,362

I need to do some simple schematics, I don't need (and would never use) 3D modelling rendering etc. For those with long memories, AutoSketch would...

- Replies

- 20

- Views

- 8,496

Hello all,

Is any good analyzing software. We have a bunch of data in text files. Need to analyse. Right now we are using DIadem. Is there any...

- Replies

- 5

- Views

- 2,283

Can someone recommend me a compact device to control logic on/off beacon according to signal from a PIR ?

Some RTU maybe. I am newbie in...

- Replies

- 6

- Views

- 2,194