Conveyor Belt

- Thread starter Hodak04

- Start date

Similar Topics

Hello,

I have a servo motor running a conveyor belt system. I do not have the exact circumference of the head pully and therefore I get some...

Good Afternoon ,

I just came out of a meeting , and the subject came up , about static buildup on a conveyor belt causing a metal detector...

Hello,

I'm currently designing a paint mixer for a mechatronics project. I've outlined the basic structure but I had two problems. For the dc...

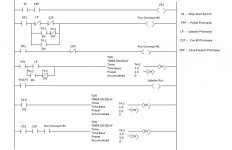

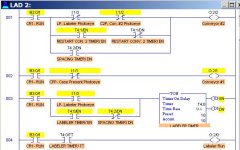

First off, I am new to the whole PLC world and was tasked with a project at work. I was given a Click C0-11dre-D, Honeywell 310G barcode scanner...

Hi guys,

Has anyone done anything like this before ?

I am working on a project where I have to count car tyres that are manually placed on a...