I’m sorry I don’t remember this better. A few years ago setting up some messaging in a ML1100 or ML1400, I selected the wrong message type and developed with it for a while. When I tried to fix it, I was unable to get it to compile. It might have been the same error you see.

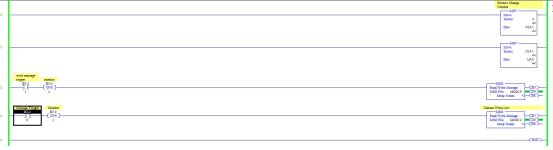

My fix was to completely delete and recreate the MSG instruction plus at least one of the MG or RI data files. I only had two messages so it wasn’t as much work as it would be for this project. You might try branching off a save, deleting the messages and data files, then create the files and a message again.

I might have found a thread here at that time with some insight on that from Ken Roach, but maybe not. That happens so often on other topics, I might be imagining it for this.

About multihop, I just pulled up a ML1100 example to confirm. Even though multihop is selected, there is a single channel 1 to EtherNet/IP device hop defined on the multihop tab. I don’t recall why, but I think I have always had to do it that way on a MicroLogix.