Is the wiring different? all ouputs wired the same

Is the power supply the same? Same power supply

Are the LEDs the same brand, model, and size? all opperate at 2-3 V, I took a separate 24VDC source and all LEDs lit when I touched the wire to their path

Do you have the 3 unlighted LEDs turned the same way with power wire to + terminals, - power wire to - terminals?

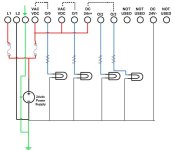

I do not have 24VDC coming off the outputs. before O0:1 lit as per the original program. Now with new test program, only O0:0 lites as it should in first version, but O0:2 and O0:3 are ON at LEDs in the PLC unit indicators and Micro Logix ladder diagram but not on breadboard output LEDs after I edited the original program to include o0:2 and O0:3 turning on. I branched these two under O0:1 in the program. I used a switch for I1:3 to turn all of them ON.

I figure when the PLC LEDs go on, I should have 24V at the terminals to feed output

I have a 1 amp fuse before the PLC and before that I had .6 amp but blew them

thanks so much for your reply

Is the power supply the same? Same power supply

Are the LEDs the same brand, model, and size? all opperate at 2-3 V, I took a separate 24VDC source and all LEDs lit when I touched the wire to their path

Do you have the 3 unlighted LEDs turned the same way with power wire to + terminals, - power wire to - terminals?

I do not have 24VDC coming off the outputs. before O0:1 lit as per the original program. Now with new test program, only O0:0 lites as it should in first version, but O0:2 and O0:3 are ON at LEDs in the PLC unit indicators and Micro Logix ladder diagram but not on breadboard output LEDs after I edited the original program to include o0:2 and O0:3 turning on. I branched these two under O0:1 in the program. I used a switch for I1:3 to turn all of them ON.

I figure when the PLC LEDs go on, I should have 24V at the terminals to feed output

I have a 1 amp fuse before the PLC and before that I had .6 amp but blew them

thanks so much for your reply

Last edited: