RheinhardtP

Lifetime Supporting Member + Moderator

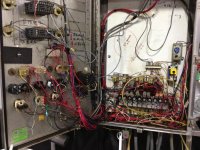

It looks like something i would test with in my own workshop. Definitely not something i would deliver to a client. It looks messy. There are neater ways to run wires to switches in doors.

What Erik was saying is the person that did this at his supplier did not have pride in his work and i agree 100%. It will take 5 min to neaten up the wires not a big job. You wont rewire the panel.

What Erik was saying is the person that did this at his supplier did not have pride in his work and i agree 100%. It will take 5 min to neaten up the wires not a big job. You wont rewire the panel.