danatomega

Lifetime Supporting Member

Well, let's start at the beginning

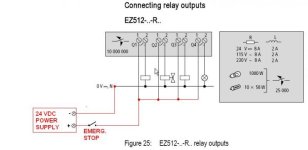

1. You really need some hard wired relays (safety relays are best) and a normally open pushbutton and a normally closed pushbutton. The N.O. will energize the relay, the relay will latch on and the N.C. will turn the circuit off. Contacts from the relay will provide power to the I/O and you'll probably want a contact to run a relay to power the VFD. This is a simplified version of getting the system powered up and provide for a stop (possibly and e-stop if you don't want to go the safety relay route) - I'm not in any way condoning the simplified route, but I suspect there are a number of references to a more robust power on circuit - this is merely the nuts and bolts).

2. You'll need to set parameter P5.01 and P5.02 to the two different speeds (in frequency - 0.0 to 400 Hz). Page 4-38 in the manual:

http://www.automationdirect.com/static/manuals/gs1m/ch4.pdf

3. You'll also need to set parameter P3.02 and P3.03 to '3' which is the multispeed select for DI3 and DI4. Page 4-21.

4. You need to wire a power on signal to I1 of the PLC.

5. Cycle Start Pushbutton to I2

6. Cycle Stop Pushbutton to I3

7. PhotoEye 1 to I4, PhotoEye 2 to I5.

8. According to the VFD manual - do NOT connect external voltage sources to the Digital Inputs. They appear to need dry contact closures - so, relays from Radio Shack or otherwise. It doesn't look like the solid state relays will work for this since the maximum off state current is 1 mA for the VFD inputs and the leakage current from the S.S. relays would keep the VFD input turned on.

8. Q1 to VFD RUN input

9. Q2 to VFD DI3, Q3 to VFD DI4. You may be able to just jumper DI3 and use DI4 to shift to the other speed.

10. Q3 to spray head.

I'll have another go at the PLC sequence ...

1. You really need some hard wired relays (safety relays are best) and a normally open pushbutton and a normally closed pushbutton. The N.O. will energize the relay, the relay will latch on and the N.C. will turn the circuit off. Contacts from the relay will provide power to the I/O and you'll probably want a contact to run a relay to power the VFD. This is a simplified version of getting the system powered up and provide for a stop (possibly and e-stop if you don't want to go the safety relay route) - I'm not in any way condoning the simplified route, but I suspect there are a number of references to a more robust power on circuit - this is merely the nuts and bolts).

2. You'll need to set parameter P5.01 and P5.02 to the two different speeds (in frequency - 0.0 to 400 Hz). Page 4-38 in the manual:

http://www.automationdirect.com/static/manuals/gs1m/ch4.pdf

3. You'll also need to set parameter P3.02 and P3.03 to '3' which is the multispeed select for DI3 and DI4. Page 4-21.

4. You need to wire a power on signal to I1 of the PLC.

5. Cycle Start Pushbutton to I2

6. Cycle Stop Pushbutton to I3

7. PhotoEye 1 to I4, PhotoEye 2 to I5.

8. According to the VFD manual - do NOT connect external voltage sources to the Digital Inputs. They appear to need dry contact closures - so, relays from Radio Shack or otherwise. It doesn't look like the solid state relays will work for this since the maximum off state current is 1 mA for the VFD inputs and the leakage current from the S.S. relays would keep the VFD input turned on.

8. Q1 to VFD RUN input

9. Q2 to VFD DI3, Q3 to VFD DI4. You may be able to just jumper DI3 and use DI4 to shift to the other speed.

10. Q3 to spray head.

I'll have another go at the PLC sequence ...